When it comes to manufacturing, it’s impossible to overlook Henry Ford’s contribution. Whether you like it or not, the owner of the world’s largest automobile manufacturer is a pioneer in industrialization and has succeeded in changing the paradigm of goods production. Prior to 1913, only officials and presidents drove.

Cars can now be traded at reasonable prices as a result of Ford’s industrialization. Since then, the manufacturing industry has grown and expanded beyond the automotive industry. What, then, is the definition of a manufacturing company?

Understanding The Manufacturing Industry

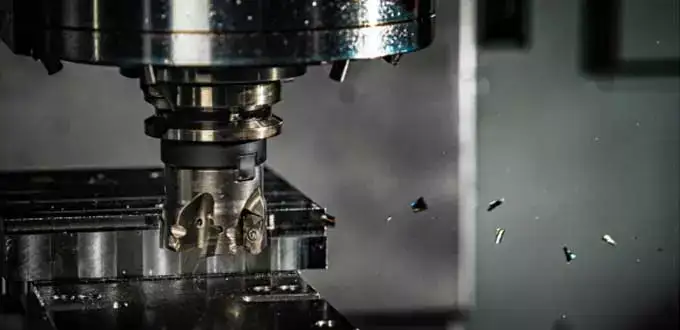

Manufacturing is simply a business that supplies raw materials to be turned into a desired output. The greater the market demand, the more supply procedures the business will undertake to suit consumer needs.

Also read: What is That Supply Chain Management?

Although this industry is similar to the trading industry in practice, the presence of factories in the manufacturing industry distinguishes it. The factory is used to manage and produce goods for sale.

Types of Manufacturing Companies

There are several industrial areas in Indonesia, including Tangerang, Pulogadung in Jabodetabek, and Pandaan in East Java. Manufacturing, like other industries, is classified into several types based on the product.

1. Clothing and Textile Company

This industry manufactures items such as ready-to-wear clothing or fabrics for distribution to various regions. Polychem Indonesia Tbk and Trisula Textile Industry are two factories in Indonesia’s clothing and textile industry.

2. A Company That Specializes in Communication, Transportation, and Electronics

Other types of manufacturers create tools to help with communication, mobility, and audio-visual needs. This is an important industry in everyday life. Goodyear Indonesia and Polytron Tbk are two companies in this industry in Indonesia.

Also read: Understanding and Starting a Retail Business for Novices

3. Petroleum, chemicals, and plastics

Following that is the production of oil, chemicals, and plastics. This industry requires raw material suppliers, which typically come from mines, in addition to factories.

This industry is one of Indonesia’s most important commodities, and it is frequently exported abroad. Holcim Industry Tbk and Indocement Tunggal Prakarsa are two Indonesian companies involved in this type of manufacturing.

4. Wood, Leather, and Paper

The wood, leather, and paper industries are also examples of natural resource-based manufacturing in our country.

The main ingredients for this item are typically sourced from plantations in Indonesia. This industry includes factories such as Alam Karya Tunggal Tbk and Champions Pacific Industry.

5. Food and Beverage

Food and beverage manufacturing is another type of manufacturing that can be found in almost every country.

This industry is rapidly expanding in Indonesia, and there are many enthusiasts. The Mayora Group and Indofood are two of our country’s leading food and beverage manufacturers.

System for Manufacturing Companies

Every business must have its own production and purchasing system. The effectiveness of this system has been confirmed because it includes many elements, beginning with human resource management, work productivity, product quality, and a maximum inventory system.

The following systems, among others, are used to better understand manufacturing companies:

The Use of The Pull System

The term “pull system” refers to the activities carried out by the company in the form of material withdrawals only when needed. Its primary goal is to strengthen the company’s economy and increase flexibility.

Quality Enhancement

In addition to the pull system, manufacturers always strive to improve quality through an ongoing quality testing process on the products they sell.

This is done to ensure that production quality is maintained and that factories do not lose their loyal customers.

Execution and Planning

It takes careful planning to create a product. The same is true for the manufacturing sector. In order to increase sales, companies must not only plan well, but also execute well in order to reduce waste.

Complete Reconstruction

Finally, reflection and improvement are critical components of running a manufacturing company system.

As a result of these advancements, the industry will be able to grow as expected and will be able to meet market demand without sacrificing quality.

Method of Manufacturing Companies Sales

Aside from the system, manufacturing companies use a variety of sales methods. Here’s the verdict.

- Prepare to Stock

This method entails traditional purchasing and selling activities such as manufacturing, stock holding, and selling. This method is typically used by automotive and electronics manufacturers. - Custom-Made

Products are made based on customer needs in the second method, which does not provide stock. Handicraft factories and wooden furniture are two industries that use the make to order method. - Prepare to Assemble

The final method is a hybrid of the previous two. This method is used by industries that create a product as stock and then modify it based on the order.

Laptop manufacturers are frequent users of the make to assemble method. Typically, factory-produced laptops are standard and consistent.

However, at the customer’s request, additional specifications are added, causing the product’s quality and specifications to differ from those available at the factory.

Conclusion

Manufacturing, like other industries, involves a large amount of capital and stakeholders in the company. This is why accurate financial reports from each division are required. Imagine the difficulties that employees would face if this was done manually.

Aside from stock and sales, there are numerous other items that must be properly recorded in order for financial conditions to remain stable. You can use the IREAP POS application as a workaround. This application is a stock and employee performance calculator.

On a smaller scale, iREAP POS functions as an online and offline cashier tool, recording incoming and outgoing goods in order to calculate daily income. This application can also be used for bookkeeping, eliminating the need for a manual method of recording.

That concludes our examination of the concept of a manufacturing company. I hope you find it useful.